Intelligent paging coding machine and paging coding method

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-07-05 17:10

- Views:

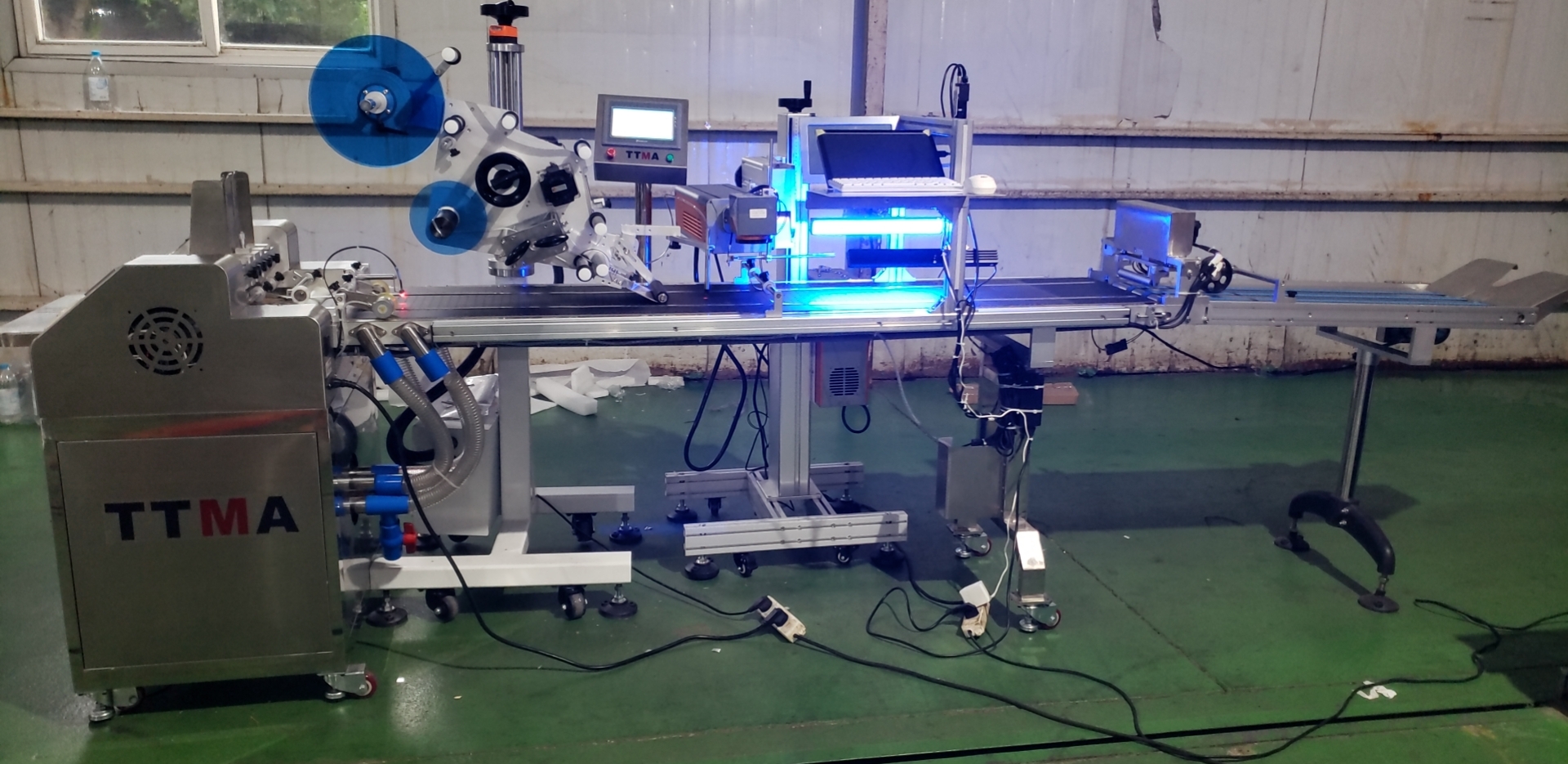

(Summary description)Technical features of intelligent paging code printer: 1. The patented technology of the utility model relates to an intelligent paging and coding machine, which includes a body workbench, on which a paper feeding mechanism, a paper inspection mechanism, an inductive code spraying mechanism and a paper pressing wheel are arranged according to the paper movement order. 2. An intelligent paging and coding machine according to claim 1, which is characterized in that the edge of the paper side of the body is connected with an electrostatic protection brush through screws. The electrostatic protection brush is made of superconducting elastic steel fiber material, and the screws are connected with wires and plugs, which are successively fixed on a group of columns at the bottom of the body. 3. An intelligent paging and coding machine according to claim 1, the paper mechanism described in its feature includes two baffles and pulleys arranged on the machine body, the two baffles are arranged in parallel and move along the paper direction, the pulley drives the belt to rotate between the two baffles and their surfaces, the belt is provided with a paper feed wheel, the paper feed wheel is on its roller, and the roller is provided with a paper feed wheel; For the gap between the paper inlet pulley and the belt pulley, the paper inlet pulley is fixedly connected with a baffle plate. The paper inlet pulley also provides a reverse rotating paper inlet pulley reverse push pulley, which is arranged on the workbench of the body and connected with the motor through the support, belt pulley, paper pulley and reverse push pulley respectively. A coding method of intelligent paging coder, which applies intelligent paging coder for paging coding, is characterized by the following specific implementation: Step 1. Return all the paper to be flipped and coded on the belt pulley between the two baffles, transfer some paper between the paper feeding wheel and the belt pulley, and gradually transfer the remaining paper between the paper feeding wheel and the belt pulley after all parts pass. Step 2. The paper between the feed wheel and the belt wheel is transferred to the paper side between the reverse wheel, between the reverse wheel and the belt wheel in turn, and through the rotating belt wheel. Step 3. When the paper moves under the lens of the camera, the camera takes photos for many times and transmits the photos to the industrial computer. Step 4. The data processing module in the industrial computer compares the captured photos with the stored coding samples, and converts the comparison results into electrical signals and sends them to the coder; If the result is on the back of the paper, the front and back of the paper need to be stenciled; If the comparison result is blank on the back of the paper, only the front of the paper needs to be stenciled. Step 5. The paper passes the color block color circle, the color code sensor senses the color block signal of the color block color circle on the workbench of the body, the color code sensor sends the color block signal to the encoder, and the encoder controls the work of the upper nozzle and the lower nozzle according to the comparison results. Step 6. Under the rotation of the paper pressing wheel, the coded paper is moved to the paper output side of the machine body workbench and flattened by the paper pressing wheel. After the electrostatic protection brush eliminates the static electricity, the paper is finally collected. Technical summary of intelligent paging and coding machine The invention discloses an intelligent paging and coding machine, which comprises a body workbench. The body workbench is successively provided with a paper feeding mechanism, a paper inspection mechanism, an induction coding mechanism and a paper pressing wheel according to the paper movement order. The patented technology has fast paging speed and accurate coding, and realizes the integration of paging and coding of paper documents. It also discloses a method of paging code, which places the body of paging code paper between the worktable baffles, automatically identifies the paper content detection mechanism, judges the feedback system through paging through the paper feeding wheel and return wheel, and combines the paging code mechanism with the induction equipment to uniformly collect and stack operations, forming an integrated process of paging coding of paper documents, synchronously improving the efficiency and accuracy of paper paging coding.

Intelligent paging coding machine and paging coding method

(Summary description)Technical features of intelligent paging code printer:

1. The patented technology of the utility model relates to an intelligent paging and coding machine, which includes a body workbench, on which a paper feeding mechanism, a paper inspection mechanism, an inductive code spraying mechanism and a paper pressing wheel are arranged according to the paper movement order.

2. An intelligent paging and coding machine according to claim 1, which is characterized in that the edge of the paper side of the body is connected with an electrostatic protection brush through screws. The electrostatic protection brush is made of superconducting elastic steel fiber material, and the screws are connected with wires and plugs, which are successively fixed on a group of columns at the bottom of the body.

3. An intelligent paging and coding machine according to claim 1, the paper mechanism described in its feature includes two baffles and pulleys arranged on the machine body, the two baffles are arranged in parallel and move along the paper direction, the pulley drives the belt to rotate between the two baffles and their surfaces, the belt is provided with a paper feed wheel, the paper feed wheel is on its roller, and the roller is provided with a paper feed wheel; For the gap between the paper inlet pulley and the belt pulley, the paper inlet pulley is fixedly connected with a baffle plate. The paper inlet pulley also provides a reverse rotating paper inlet pulley reverse push pulley, which is arranged on the workbench of the body and connected with the motor through the support, belt pulley, paper pulley and reverse push pulley respectively.

A coding method of intelligent paging coder, which applies intelligent paging coder for paging coding, is characterized by the following specific implementation:

Step 1. Return all the paper to be flipped and coded on the belt pulley between the two baffles, transfer some paper between the paper feeding wheel and the belt pulley, and gradually transfer the remaining paper between the paper feeding wheel and the belt pulley after all parts pass.

Step 2. The paper between the feed wheel and the belt wheel is transferred to the paper side between the reverse wheel, between the reverse wheel and the belt wheel in turn, and through the rotating belt wheel.

Step 3. When the paper moves under the lens of the camera, the camera takes photos for many times and transmits the photos to the industrial computer.

Step 4. The data processing module in the industrial computer compares the captured photos with the stored coding samples, and converts the comparison results into electrical signals and sends them to the coder; If the result is on the back of the paper, the front and back of the paper need to be stenciled; If the comparison result is blank on the back of the paper, only the front of the paper needs to be stenciled.

Step 5. The paper passes the color block color circle, the color code sensor senses the color block signal of the color block color circle on the workbench of the body, the color code sensor sends the color block signal to the encoder, and the encoder controls the work of the upper nozzle and the lower nozzle according to the comparison results.

Step 6. Under the rotation of the paper pressing wheel, the coded paper is moved to the paper output side of the machine body workbench and flattened by the paper pressing wheel. After the electrostatic protection brush eliminates the static electricity, the paper is finally collected.

Technical summary of intelligent paging and coding machine

The invention discloses an intelligent paging and coding machine, which comprises a body workbench. The body workbench is successively provided with a paper feeding mechanism, a paper inspection mechanism, an induction coding mechanism and a paper pressing wheel according to the paper movement order. The patented technology has fast paging speed and accurate coding, and realizes the integration of paging and coding of paper documents. It also discloses a method of paging code, which places the body of paging code paper between the worktable baffles, automatically identifies the paper content detection mechanism, judges the feedback system through paging through the paper feeding wheel and return wheel, and combines the paging code mechanism with the induction equipment to uniformly collect and stack operations, forming an integrated process of paging coding of paper documents, synchronously improving the efficiency and accuracy of paper paging coding.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-07-05 17:10

- Views:

Technical features of intelligent paging code printer:

1. The patented technology of the utility model relates to an intelligent paging and coding machine, which includes a body workbench, on which a paper feeding mechanism, a paper inspection mechanism, an inductive code spraying mechanism and a paper pressing wheel are arranged according to the paper movement order.

2. An intelligent paging and coding machine according to claim 1, which is characterized in that the edge of the paper side of the body is connected with an electrostatic protection brush through screws. The electrostatic protection brush is made of superconducting elastic steel fiber material, and the screws are connected with wires and plugs, which are successively fixed on a group of columns at the bottom of the body.

3. An intelligent paging and coding machine according to claim 1, the paper mechanism described in its feature includes two baffles and pulleys arranged on the machine body, the two baffles are arranged in parallel and move along the paper direction, the pulley drives the belt to rotate between the two baffles and their surfaces, the belt is provided with a paper feed wheel, the paper feed wheel is on its roller, and the roller is provided with a paper feed wheel; For the gap between the paper inlet pulley and the belt pulley, the paper inlet pulley is fixedly connected with a baffle plate. The paper inlet pulley also provides a reverse rotating paper inlet pulley reverse push pulley, which is arranged on the workbench of the body and connected with the motor through the support, belt pulley, paper pulley and reverse push pulley respectively.

A coding method of intelligent paging coder, which applies intelligent paging coder for paging coding, is characterized by the following specific implementation:

Step 1. Return all the paper to be flipped and coded on the belt pulley between the two baffles, transfer some paper between the paper feeding wheel and the belt pulley, and gradually transfer the remaining paper between the paper feeding wheel and the belt pulley after all parts pass.

Step 2. The paper between the feed wheel and the belt wheel is transferred to the paper side between the reverse wheel, between the reverse wheel and the belt wheel in turn, and through the rotating belt wheel.

Step 3. When the paper moves under the lens of the camera, the camera takes photos for many times and transmits the photos to the industrial computer.

Step 4. The data processing module in the industrial computer compares the captured photos with the stored coding samples, and converts the comparison results into electrical signals and sends them to the coder; If the result is on the back of the paper, the front and back of the paper need to be stenciled; If the comparison result is blank on the back of the paper, only the front of the paper needs to be stenciled.

Step 5. The paper passes the color block color circle, the color code sensor senses the color block signal of the color block color circle on the workbench of the body, the color code sensor sends the color block signal to the encoder, and the encoder controls the work of the upper nozzle and the lower nozzle according to the comparison results.

Step 6. Under the rotation of the paper pressing wheel, the coded paper is moved to the paper output side of the machine body workbench and flattened by the paper pressing wheel. After the electrostatic protection brush eliminates the static electricity, the paper is finally collected.

Technical summary of intelligent paging and coding machine

The invention discloses an intelligent paging and coding machine, which comprises a body workbench. The body workbench is successively provided with a paper feeding mechanism, a paper inspection mechanism, an induction coding mechanism and a paper pressing wheel according to the paper movement order. The patented technology has fast paging speed and accurate coding, and realizes the integration of paging and coding of paper documents. It also discloses a method of paging code, which places the body of paging code paper between the worktable baffles, automatically identifies the paper content detection mechanism, judges the feedback system through paging through the paper feeding wheel and return wheel, and combines the paging code mechanism with the induction equipment to uniformly collect and stack operations, forming an integrated process of paging coding of paper documents, synchronously improving the efficiency and accuracy of paper paging coding.

Scan the QR code to read on your phone

-

Tel

-

QQ

-

Wechat

-

Top

Tel: 020-87470512/18026254588(Wechat )

Email: ttma_gz@163.com

HO: Room 1208, Baiyun Electric Technology Building, 1633 Beitai Road, Baiyun District, Guangzhou

Add: No. 37, Fenghe Jiangniu Road, Renhe Town, Baiyun District, Guangzhou

No.19, Taocun Industrial Zone, Beijiao Town, Shunde District, Foshan City, Guangdong Province

Copyright © 2020 Guangzhou Tengtian Machinery Industry Co., Ltd. All Rights reserved 粤ICP备20010952号

By: 300.cn