-

Full automatic labeling, identification and elimination machine

- Technical parameters:

* labeling accuracy: ± 1mm (excluding product and label errors), and the adjustment level significantly affects the labeling accuracy;

* labeling speed: 40 ~ 120 pieces / min, depending on product length and quality;

* applicable products: samples provided by customers;

* applicable label: the roll label provided by the customer;

* applicable power supply: 220V 50 / 60Hz -

- Tel: 020-87470512 Contact Us

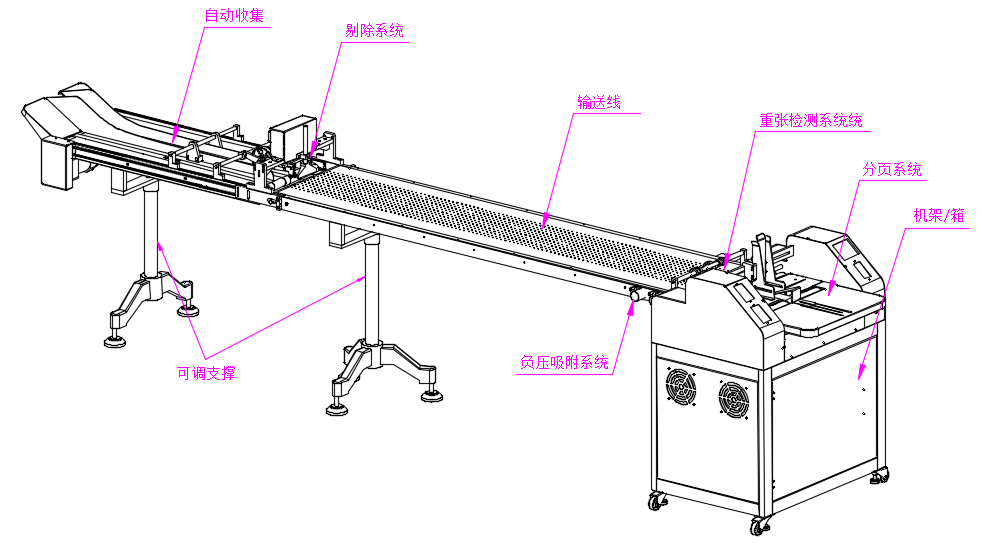

1、 Structure / system introduction:

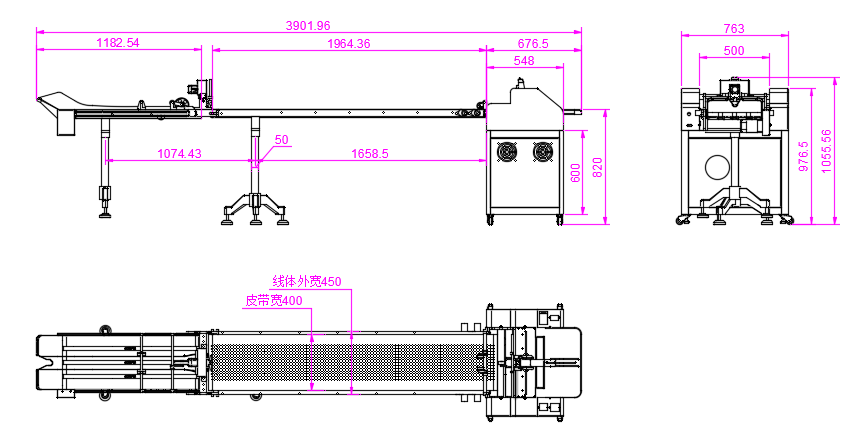

2、 Overall dimension:

3、 Electrical composition and technical specifications (non-standard machine)

1. Overall dimension: length * width * height = 3900 * 760 * 820mm

(Note: the conveyor belt is 400mm wide and 2000mm long)

2. Weight: About 300kg

3. Power supply: 220VAC

4. Total power: About 2.5kW

5. Belt running speed: 0-70m / min

6. Control mode: double frequency conversion speed regulation

7. Paging principle: "static friction type", lower discharge (3 friction belts)

8. Applicable product types: various plastic bags, cartons, paper labels, film labels, cartons / cards

9. Applicable product specification: length * width * thickness = (65-350) * (25-400) * (0.1-3) mm

10. Negative pressure adsorption: medium pressure large flow fan

11. Conveyor belt type: black matte PVC

12. Accuracy of re tensioning side inspection: ± 0.1mm

13. Accuracy of paging position: ± 1mm

14. Rejection system: Double rejection system, "air blowing type" and "pressing roller type"

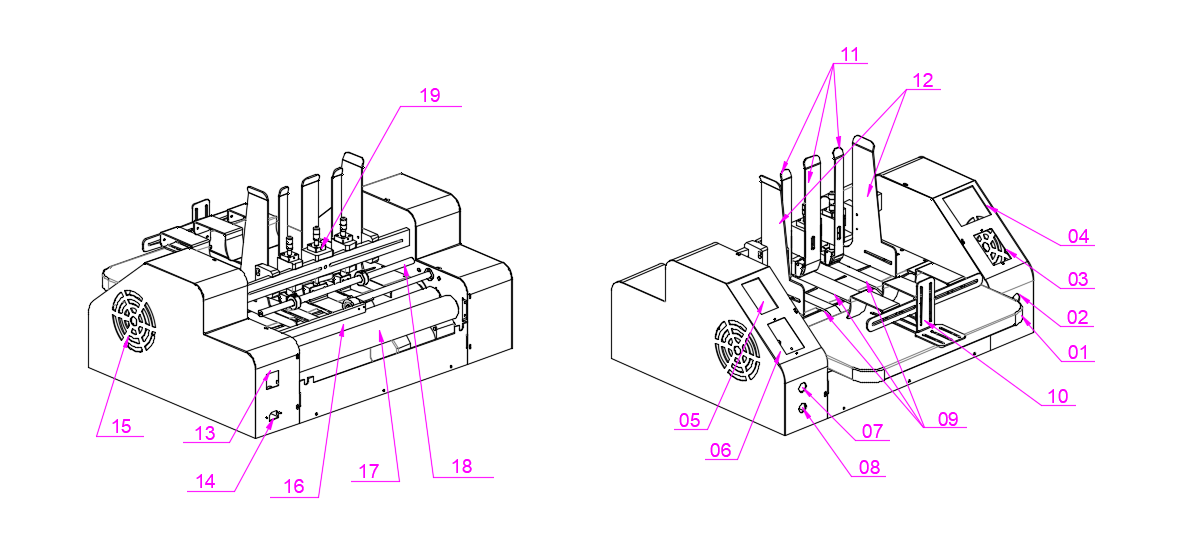

4、 Specific function introduction and debugging method

As shown in the figure:

1. Stop button: red stop button. Press this button to stop the machine

2. Start button: green start button. Press this button and the machine will run

3. Paging motor speed regulation control panel: adjust the knob to adjust the output frequency of the frequency converter, so as to adjust the paging belt speed; Clockwise adjustment,

Reverse time adjustment deceleration (see the operation manual of frequency converter for details)

4. Touch screen: see details for specific operation and function introduction

5. Speed regulation control panel of receiving motor: adjust the knob to adjust the output current of the governor, so as to adjust the speed of receiving line; Adjust the acceleration in time,

Reverse time adjustment deceleration

6. Speed regulation control panel of conveying motor: adjust the knob to adjust the output frequency of frequency converter so that the conveying line speed; Adjust acceleration in time and reverse time

Adjust deceleration

7. Fan switch: press the button to turn on the power supply of the fan and start the fan; Press the button again to disconnect the power supply of the fan and stop the fan

8. Power switch: turn the switch clockwise to turn on the power; Turn the switch counterclockwise to disconnect the power supply

9. Paging belt: the paging friction belt is composed of 3 pieces. The belt position can be adjusted as required, and the number of belts can be selected according to the size of the product

10, the supporting plate can be adjusted back and forth to hold the position of the product about 1/3, so as to reduce product overlap probability.

11. Paging grid plate: it can be adjusted according to the thickness of the product. The front end of the auxiliary product is neat and prevents the product from leaning forward due to gravity

12. Paging side plate: also known as material box plate, it is used for material discharge reference and material feeding guidance. It is generally adjusted according to the product width, leaving a gap of about 1-2mm

13. Power plug-in board: provide AC220V power supply with power less than 1000W (included)

14. Power cord plug: power plug of low-power equipment

15. Ventilation window: provide heat exchange cooling of electrical components (hands or foreign matters are not allowed to enter)

16. Duplicate page detection roller: white, used to detect the thickness of products, and the surface of the roller must be kept clean

17. Conveying driving roller: conveying belt power roller

18. Paging strip pressing: paging discharge strip pressing to prevent product warpage and affect the smooth feeding

19. Separator: it is used for paging core components. Different separators may be required according to different products. Pay attention to cleaning. Adjust clockwise to increase friction

Counterclockwise rotation reduces friction,

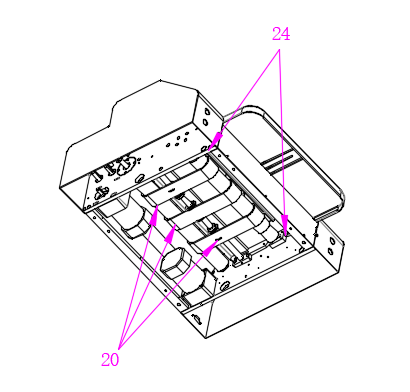

20. Position adjustment of paging belt (3 pieces): it is used to adjust the position of paging belt, loosen the control wheel corresponding to the belt to be adjusted, and move it manually

Lock the control wheel when it reaches the proper position

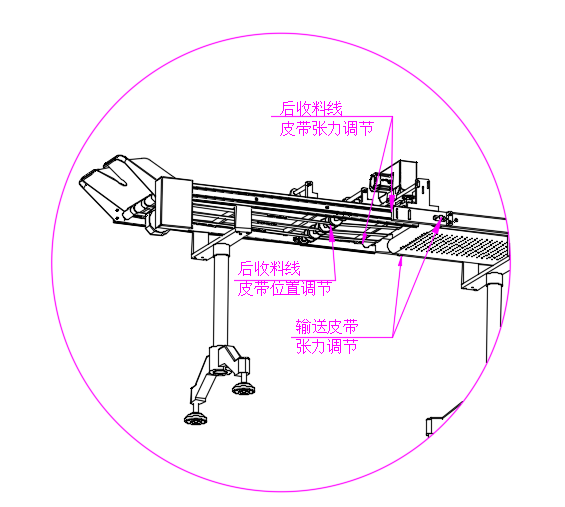

21. Tension adjustment of conveyor belt: rotate and tension clockwise and rotate and relax counterclockwise; It is used to adjust the tension on both sides of the belt to prevent the belt from shifting to one side;

Specific adjustment method: if the belt deviates to the left, tension the left knob or loosen the right knob. If the belt deviates to the right, it is tensioned

Knob or loosen the left knob. Note: do not adjust the belt tension too much, which may damage the belt and transmission system; Pay attention to light adjustment and slow tightening.

22. Position adjustment of rear receiving belt (3 pieces): it is used to adjust the position of rear receiving belt, loosen the control wheel corresponding to the belt to be adjusted, and adjust it manually

After moving to the appropriate position, lock the control wheel

23. Belt tension adjustment of rear receiving line: please refer to the adjustment method of conveyor belt, which is omitted here

24. Tension adjustment of paging belt: please refer to the adjustment method of conveyor belt, which is omitted here

-

Tel

-

QQ

-

Wechat

-

Top

Tel: 020-87470512/18026254588(Wechat )

Email: ttma_gz@163.com

HO: Room 1208, Baiyun Electric Technology Building, 1633 Beitai Road, Baiyun District, Guangzhou

Add: No. 37, Fenghe Jiangniu Road, Renhe Town, Baiyun District, Guangzhou

No.19, Taocun Industrial Zone, Beijiao Town, Shunde District, Foshan City, Guangdong Province

Copyright © 2020 Guangzhou Tengtian Machinery Industry Co., Ltd. All Rights reserved 粤ICP备20010952号

By: 300.cn